Custom Disposable Tray from a Reliable Manufacturer

Rapid lead times: 7–10 days | Over 200,000 trays produced to date | Trusted by 150+ global partners

Comprehensive Disposable Tray Performance Evaluation

This evaluation focuses on key factors like impact resistance, durability, and freshness preservation, ensuring our trays maintain optimal performance even in demanding conditions.

Freshness Preservation

The disposable trays are engineered to reduce moisture buildup and promote airflow, helping foods like fruits, salads, and sandwiches stay crisp for up to 48 hours during transport and storage. This design minimizes quality-related returns and supports longer distribution chains, flexible delivery schedules, and efficient handling. The compartmentalized structure streamlines packing, stacking, and logistics, reducing labor time and the risk of cross-contamination, making it suitable for high-volume production and integration across multiple SKUs and batches.

Impact Resistance for Fragile Foods

For fragile items such as tofu, cakes, or delicate pastries, the disposable trays feature shock-absorbing compartments that prevent deformation and breakage. They withstand drops from up to 1.5 meters, ensuring product integrity during bulk shipping while reducing waste and returns. The trays also support efficient kitchen workflows, maintain consistent portion presentation, and enable reliable storage and stacking in warehouses. Their durable design helps businesses comply with food safety standards and provides a platform for brand differentiation through customized printing or labeling. Combined with JHPKG’s fragile goods protection solution, companies can optimize both product safety and operational efficiency across the supply chain.

Crack & Chip Resistance

Disposable Tray-Focused Manufacturing Technology for Consistent Output

When large-scale food operations demand flawless portioning and reliable performance, even small inconsistencies in tray dimensions or material quality can disrupt workflow or cause product damage. That’s why leading B2B clients choose our trays—trusted for precise manufacturing, high-quality materials, and fully customizable designs that deliver zero-compromise performance.

Edge & Rim Reinforcement Design

A reinforced rim ensures tray stability during stacking, sealing, and long-distance transport. Optimized rim geometry and controlled wall-thickness distribution increase rigidity without extra material. The rib-supported edge enhances bending resistance, maintaining tray performance under physical stress. Combined with JHPKG’s structural reinforcement solution, businesses can improve product durability, streamline packaging operations, and maintain consistent quality across SKUs and batches.

Key Structural Advantages:

-

Stacking Strength: Reinforced rims increase vertical stacking stability by 20–35%.

-

Sealing Consistency: Edge thickness maintained within ±3–5% ensures reliable sealing.

-

Bending Resistance: Rib-supported edges increase rigidity by 18–30%.

Multi-Cavity Structural Balance

In multi-cavity thermoforming, uneven material flow can cause differences in strength and shape among cavities. Optimizing runner layout, mold temperature distribution, and cavity symmetry ensures that each tray maintains consistent structural performance. This approach supports efficient production scheduling, reduced waste, and predictable performance in downstream packing and logistics.

Key Structural Advantages:

-

Flow Balance: Error controlled within ≤8–10%, preventing weak cavities and structural inconsistencies.

-

Thickness Uniformity: Bottom and corner thickness differences kept within ≤0.05–0.1 mm, reducing deformation risks in impact zones.

-

Mold Temperature Control: Differences maintained within ≤2–3°C, ensuring uniform tray quality across batches.

Anti-Warp Cooling Zones

Deep-draw and thin-wall disposable trays are prone to warping during cooling. Implementing zoned cooling technology stabilizes shrinkage, prevents edge lifting, and maintains dimensional accuracy for sealing and stacking. This method supports consistent production quality, reduced rework, and reliable packaging performance across high-volume operations.

Key Structural Advantages:

-

Improved Heat Dissipation: Zoned cooling increases efficiency by 15–25%, preventing overheating in deep sections.

-

Dimensional Stability: Tray warpage controlled within ≤1.5–2%, ensuring stable stacking and sealing alignment.

-

Stress Reduction: Enhanced cooling in deep-draw regions minimizes internal stress, reducing deformation during demolding.

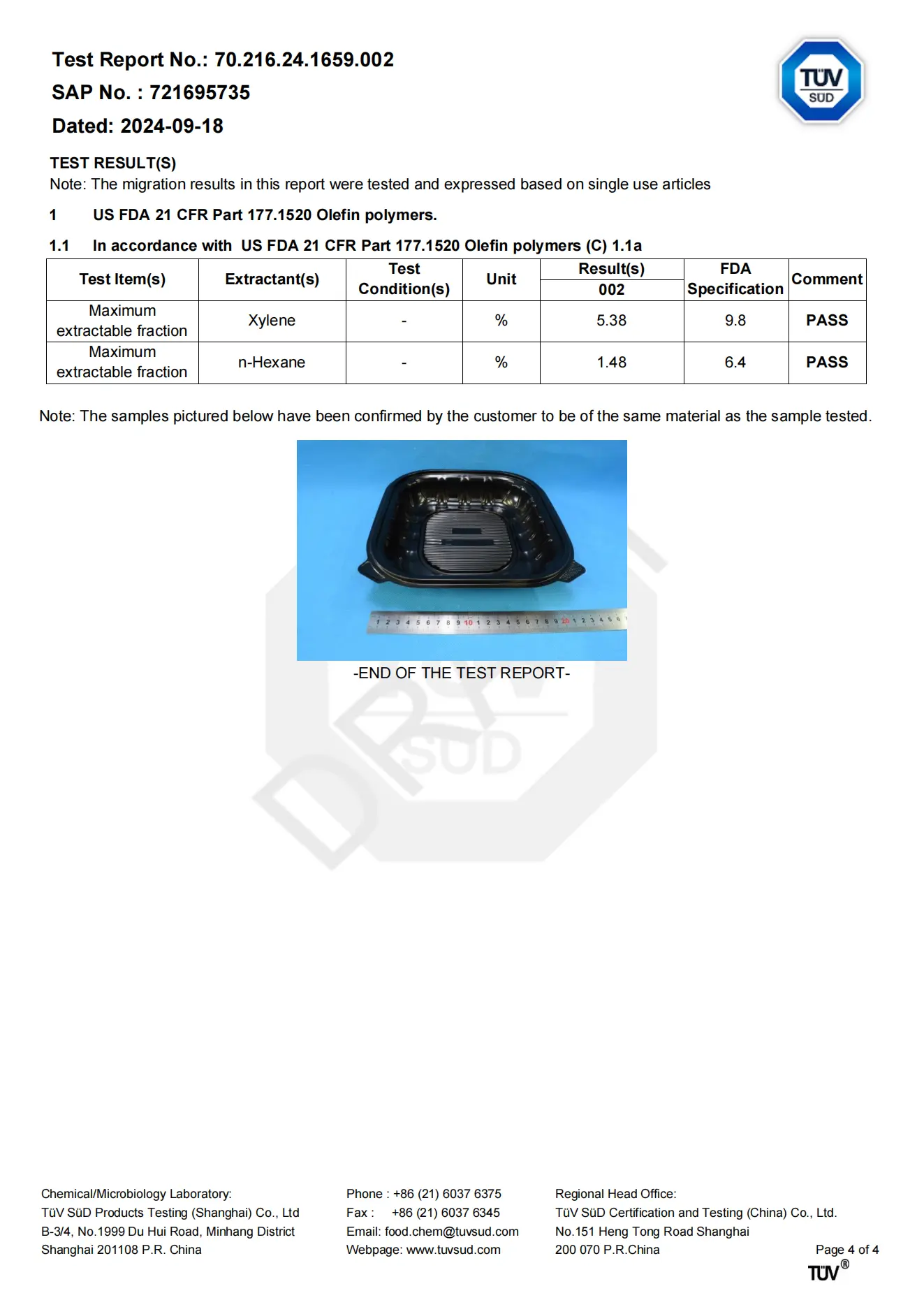

Internationally Verified Manufacturing Standards

Our disposable trays are produced in facilities that meet strict international standards for food-contact safety and factory management.

We maintain ISO 9001 quality management, ISO 22000 food safety, and BRC Packaging certifications to ensure consistent production control. All raw materials (PET, PP, PLA, bagasse) undergo SGS testing for migration, heavy metals, and temperature resistance, verifying full compliance with global food-grade regulations.