Reliable Disposable Bowl for Hot & Cold Food Service

Certified food-grade materials | Rigorous quality inspections | Expedited shipping options

Manufacturing-Level Disposable Bowl Reliability Testing

Engineered for high-volume manufacturing environments, our disposable bowl undergo strict production control to ensure consistent quality, reliable batch uniformity, and dependable performance for foodservice operations.

Compression & Stackability

Disposable bowl designs are validated to withstand vertical loads up to 30–35 kg per bowl, simulating industrial stacking and palletized shipping. Even in large shipments of 10,000+ units, deformation is prevented, ensuring each batch maintains shape and integrity.

Thermal Performance

PP bowls are tested for 100–120°C microwave heating and hot-fill applications up to 95°C. Each batch is monitored for material deformation ≤1 mm and no odor migration, supporting thousands of ready-to-heat meals daily in commercial kitchens.

Leak & Seal Integrity

Optimized disposable bowl and lid geometry prevent leaks under tilt angles up to 90° and repeated shaking over 100 cycles per unit. This ensures reliable containment during delivery, buffet service, and high-volume catering operations.

Freezer & Cold Storage Stability

PET bowls remain crack-free after 48 hours at –20°C, with dimensional tolerance within ±0.5 mm. Ideal for frozen foods, chilled prepped meals, and cold-chain logistics, tested on batches exceeding 5,000 units per lot.

Custom Disposable Bowl | Complete Sizes,colors for Every Needs

From prototype to full-scale production, our three core customization options allow you to develop unique bowl designs with accurate molds, detailed printing, and reliable color consistency.

Size

We offer flexible custom sizing services, enabling precise adjustments to product dimensions to meet client specifications and industry standards. Standard capacity options include:

• 200ml / 7oz

• 350ml / 12oz

• 500ml / 17oz

• 750ml / 25oz

• 1000ml / 34oz

Custom capacities are also available to support diverse operational needs, from small-scale orders to large-volume production. Advanced manufacturing equipment and standardized production processes ensure dimensional accuracy within ±0.5mm, providing reliable manufacturing solutions that comply with client specifications and support efficient, high-precision custom production.

Mold & Sampling

Our mold design team uses advanced technology to ensure that each customized product is fully validated before mass production:

- Mold Design: Quickly provide precise mold designs according to customer requirements, ensuring a perfect match of product dimensions and functionality, while supporting scalable and controlled production workflows.

- Digital Sampling: Using digital sampling technology, we quickly generate high-precision samples, ensuring the design meets expectations and mitigating potential issues in mass production, supporting predictable and reliable manufacturing.

Whether for sample verification or full-scale production, our mold design and sampling services provide timely and precise support, ensuring each batch meets industry standards, maintains consistent quality, and aligns with operational and production requirements.

Printing & Color

To ensure brand consistency and visual appeal, we offer various printing and color customization options:

- Full-Color Printing: Ideal for complex designs, delivering vibrant and precise colors while ensuring consistency across large-scale production runs.

- Single-Color Printing: Suitable for simple brand logos or designs with a single color tone, supporting standardized, repeatable printing processes.

- Custom Brand Colors: Precisely match client-specific colors according to brand standards, enabling reliable and high-precision customization for multi-batch production.

We also provide different printing processes, including heat transfer, screen, and offset printing, ensuring high-quality and reproducible results for both large-scale and small-batch production, supporting operational control and scalable manufacturing workflows.

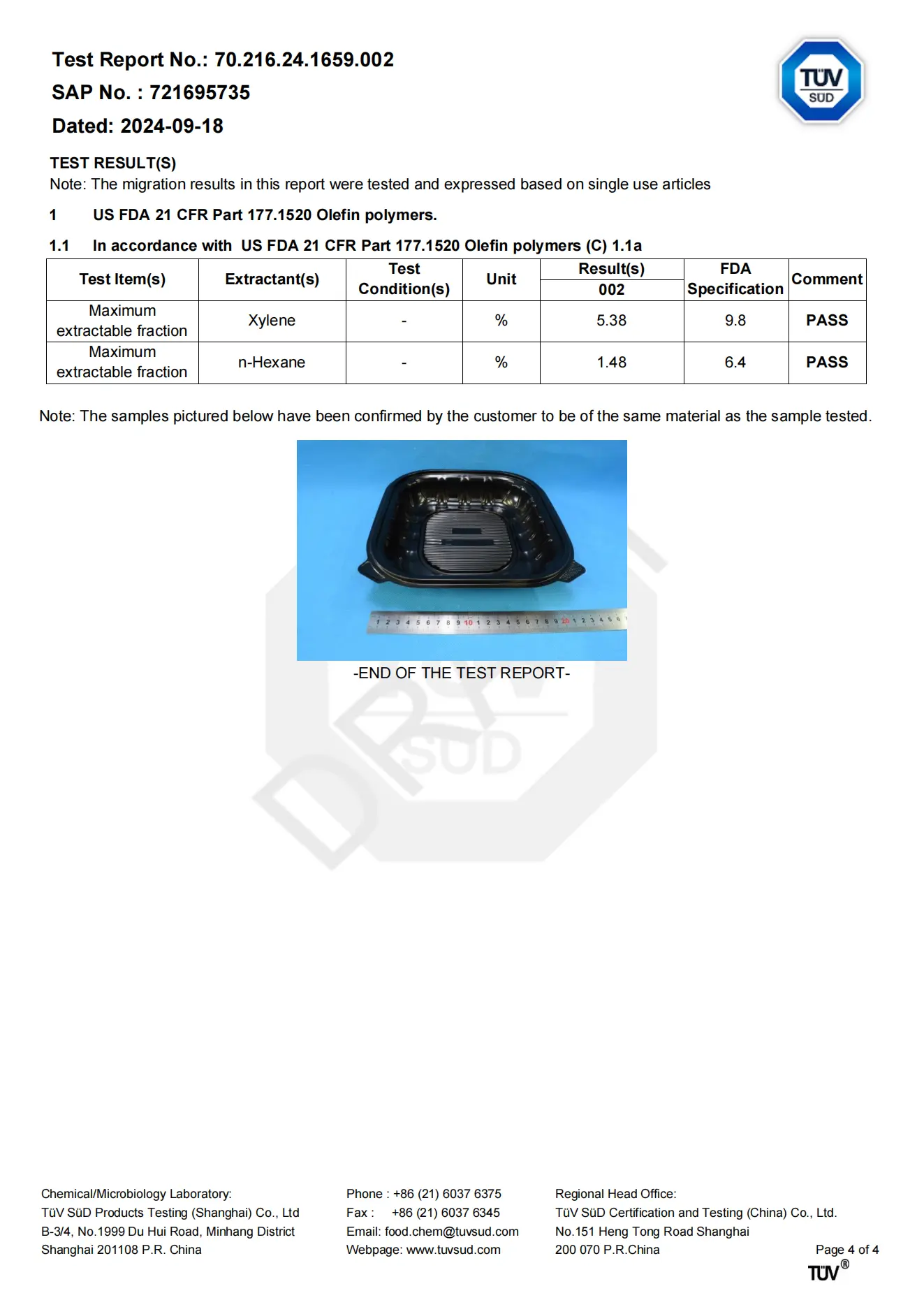

Professional Bowl Manufacturing with Verified Safety Standards

Our disposable bowls are produced under globally recognized quality and hygiene systems to ensure safe, consistent, and fully traceable manufacturing. The factory operates with ISO 9001, ISO 22000, and BRC Packaging compliance, covering every step from material handling to finished-bowl inspection. All PP, PET, PLA, and bagasse materials are verified through SGS food-contact tests, including migration limits, heavy-metal screening, and heat-resistance validation—ensuring each bowl meets international food-grade requirements for hot and cold applications.