Engineering-Centered Custom Solutions for Food-Grade Packaging

Engineered for food-grade packaging, our service delivers validated mold design, material options, and production-ready solutions for high-volume manufacturing.

Professional Custom Packaging Solutions

From material selection and mold engineering to printing and controlled manufacturing, ensuring precise specifications and consistent quality for B2B operations.

Material Flexibility

We support multiple material systems to meet strength, temperature, cost, and compliance needs.

Available materials include:

• PP / PET / PS – rigid structure, good clarity or heat resistance, suitable for lids, trays, and cups.

• Paper + PE/PLA coating – ideal for hot & cold cups, providing insulation and print performance.

• Eco materials (PLA / bagasse) – renewable options aligned with sustainability programs.

These material choices allow alignment with food-contact regulations, target cost, and performance requirements.

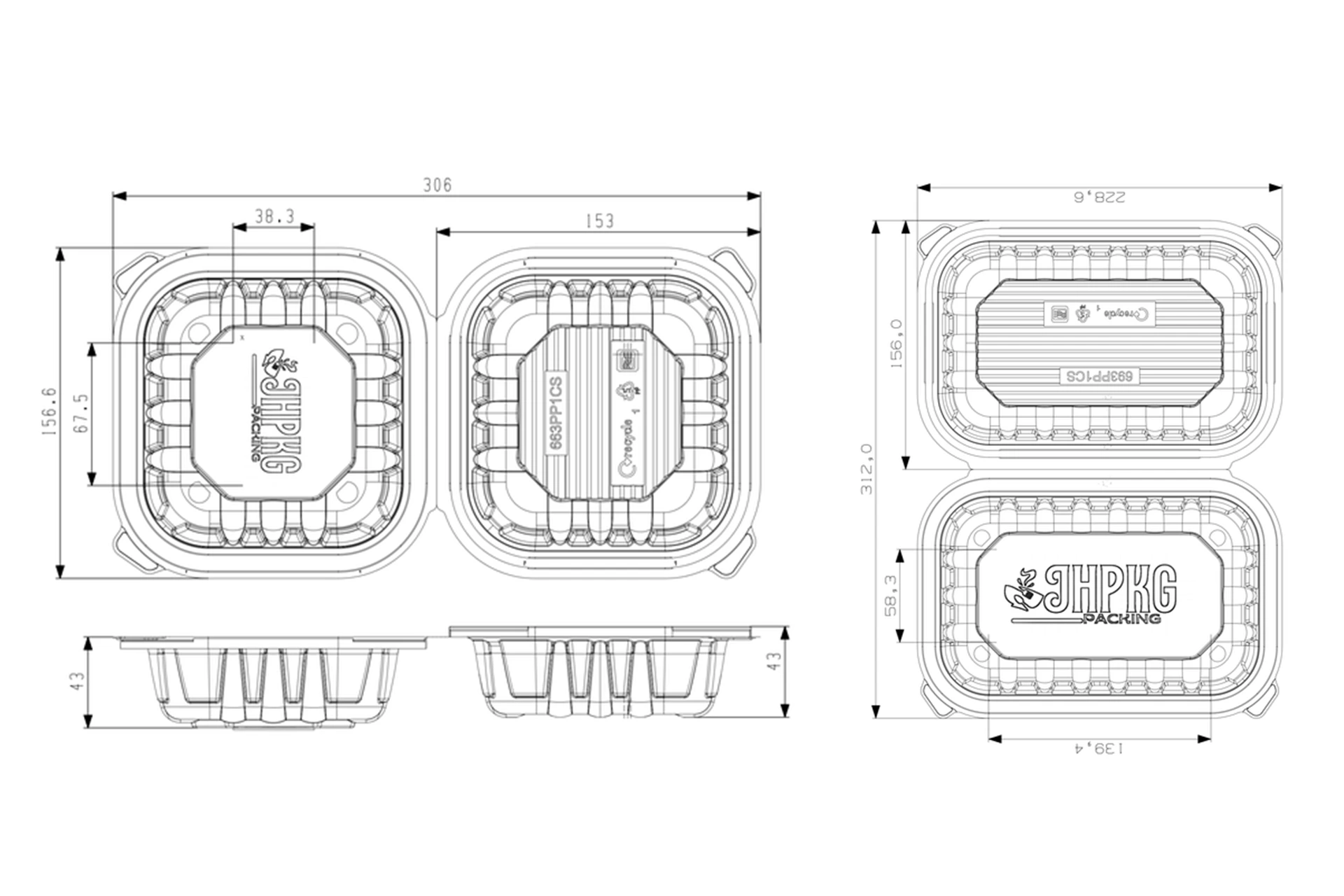

Mold Engineering Options

Two mold paths support different project scales and timelines.

Mold options:

• Standard molds – faster lead time, cost-effective for common sizes and repeat orders.

• Custom molds – tailored dimensions, geometry, and functional upgrades for new shapes or branding requirements.

Both options include digital sampling and structural validation to reduce development risk and ensure dimensional accuracy.

Printing & Color Customization

Multiple processes ensure visual consistency across high-volume production.

Printing selections:

• Full-color CMYK – for complex graphics or promotional campaigns.

• Single-color / spot-color – for brand logos with strict Pantone matching.

• Heat transfer / screen printing / offset printing – selected based on product type and batch scale.

This ensures consistent brand execution across cups, lids, and containers.

Production & Process Control

Ensures consistent product quality, process repeatability, and risk mitigation for high-volume programs.

Process controls:

• In-line quality checkpoints at critical stages

• Standardized operating procedures to reduce deviations

• Digital tracking of batch parameters for traceability

Supports long-term supply contracts, OEM programs, and multi-site production without compromising quality.

4-Step Custom Packaging Process - Simple & Transparent

We offer a fully controlled professional custom process, covering requirement confirmation, mold development, sample validation, and mass production to ensure every batch meets specifications and quality standards.

Requirement Confirmation

Specifications defined: Confirm product dimensions, materials, functional and operational requirements while aligning on logo/printing needs. Customers with existing artwork should provide PSD/AI/CDR source files to ensure print accuracy, manufacturability, and consistency during mass production.

Next Steap:

Once requirements are clarified, we proceed to mold development to ensure the custom product is controllable from the source.

Mold Development

Mold design:

Provide standard molds or fully custom molds to ensure precise product dimensions, functionality, and custom requirements, while maintaining reliability for high-volume production.

Next Step:

After mold development, high-precision samples are produced to validate that the design meets client requirements.

Sample Validation

Sample iteration:

Produce high-precision digital or physical samples; initial samples can be modified until client approval is obtained, validating structure, dimensions, functionality, and visual appearance to minimize mass production risks.

Final Step:

Once samples are approved, the process moves into standardized mass production, ensuring every batch can be executed consistently.

Mass Production

Use standardized workflows, strict quality control points, and digital batch tracking to ensure every batch matches the approved sample, achieving controllability and consistent quality for large-scale custom production.

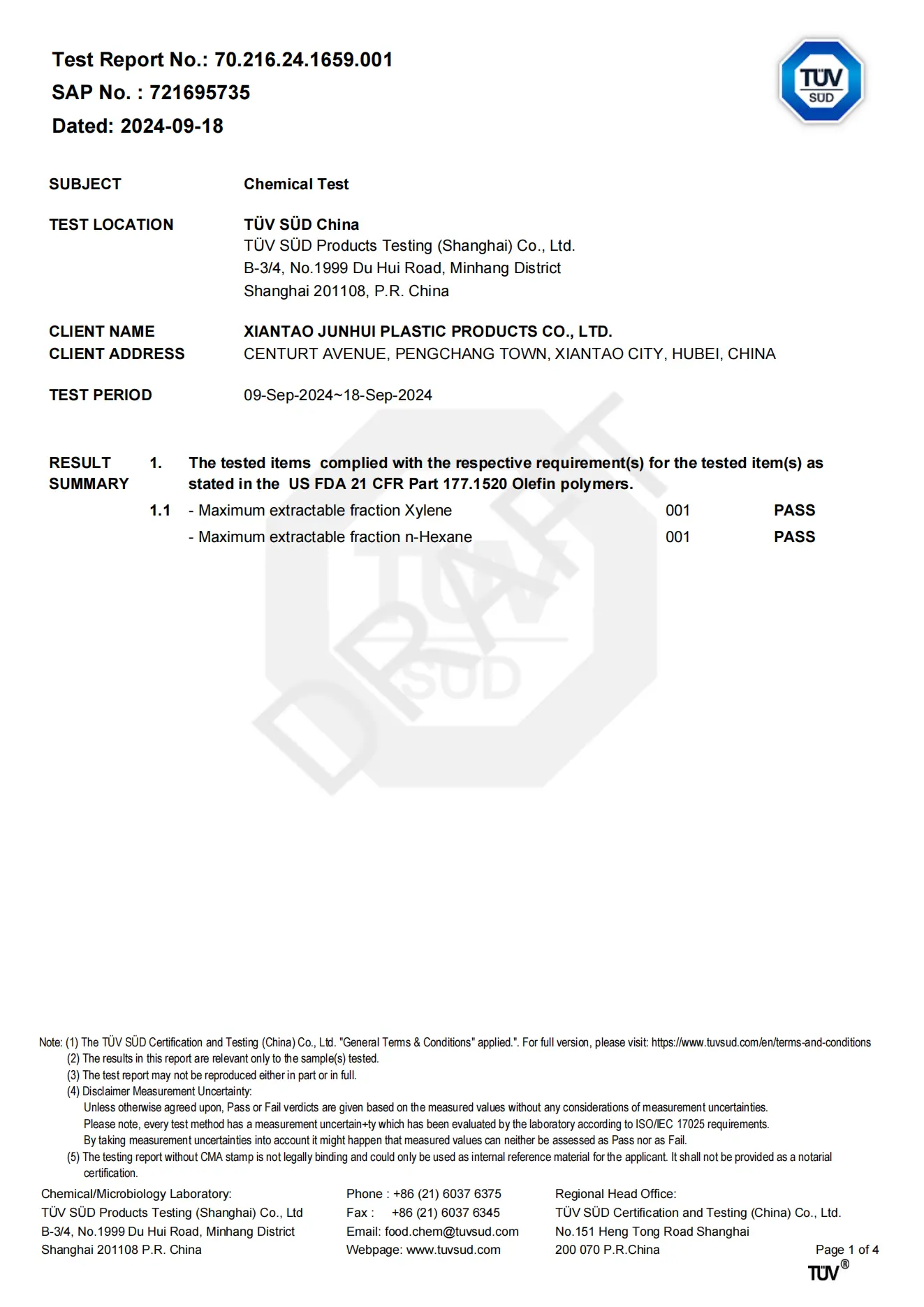

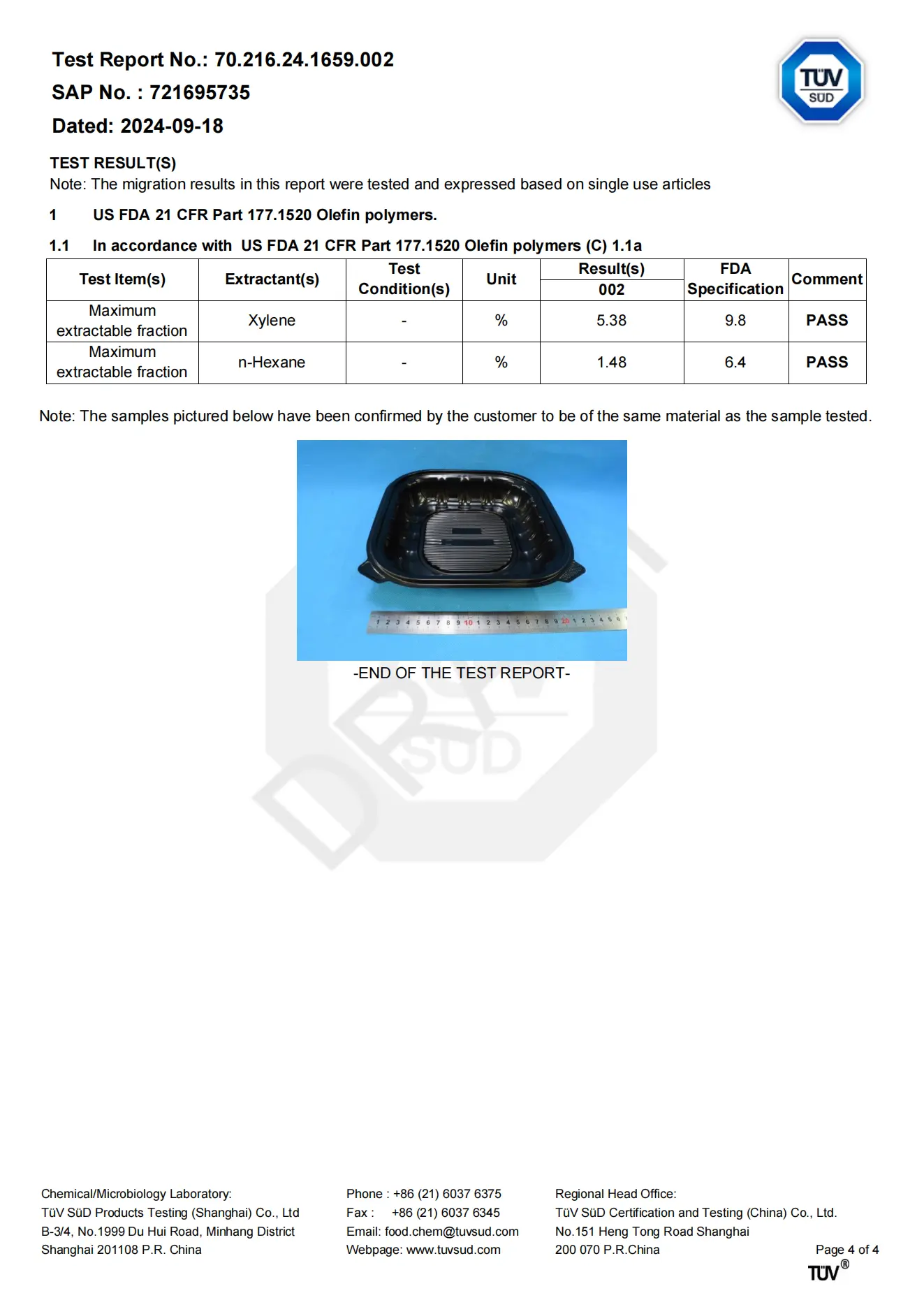

Certified Custom Packaging Compliance

Our custom disposable packaging fully complies with FDA, LFGB, and EU EN 13432 standards, ensuring the highest level of food safety, hygiene, and environmental compliance. Using certified materials and controlled manufacturing workflows, we deliver scalable custom designs with reliable performance, operational stability, and traceable production quality. These rigorous certifications and processes enable businesses to confidently manage large-scale B2B operations, maintain regulatory adherence, and reduce operational risks. With our validated production system, every batch of customized packaging meets precise specifications, supporting both brand consistency and high-volume deployment across multiple facilities.