Trusted Disposable Tray,Bowl,Box,Cup&Lids Manufacturing

Over 15 Years of Manufacturing Expertise | 2 Million+ Packagings Annually| 1,000+ Packaging Molds

Free Design Service

A Professional Team Dedicated to Your Custom Needs

Free Samples

Experience product quality firsthand, risk-free.

7-Day Express

Your order delivered quickly and reliably in one week

Comprehensive Custom Food Packaging Solutions for Every Food Business Need

From raw materials to finished products – delivering high-quality, cost-effective products through a complete, end-to-end process.

Wholesale Disposable Egg Tray

Customizable Capacity

Multiple cavity options (6/12/18/24) accommodate different SKU strategies, improving packing efficiency and inventory management.

Protective & Freshness Design

Engineered compartments stabilize each egg during transport, with vented structures that maintain freshness across long-distance supply chains.

Brand Promotion

Supports custom printing and logo marking for private-label programs, enhancing brand recognition in retail channels.

Disposable Ramen Bowl Manufacturer

Generous Capacity

Deep bowl structure holds full ramen portions with ample broth space, ensuring consistent serving across menu formats and reducing portion-related customer complaints.

High-Temperature Resistant

Stable with liquids up to 100°C, suitable for hot-fill applications, supporting efficient hot-serving workflows during peak hours and minimizing operational disruptions.

User-Friendly Design

Wide opening and smooth rim enhance filling accuracy, speeding up kitchen operations and improving end-customer dining experience.

Printing Options

Compatible with UV, screen, and digital printing for branding, seasonal graphics, or visual uniformity, reinforcing brand recognition.

Dual-Color Food Box Manufacturer Supply

Dual-Color Design

Enhances product appeal and supports menu tiering, allowing retailers and foodservice operators to differentiate premium or limited-edition offerings, improving customer perception and reducing confusion over portion types.

Protective Compartments

Keeps ingredients separated to maintain texture and flavor, ensuring consistent meal quality, minimizing customer complaints, and supporting operational efficiency across diverse cuisine formats.

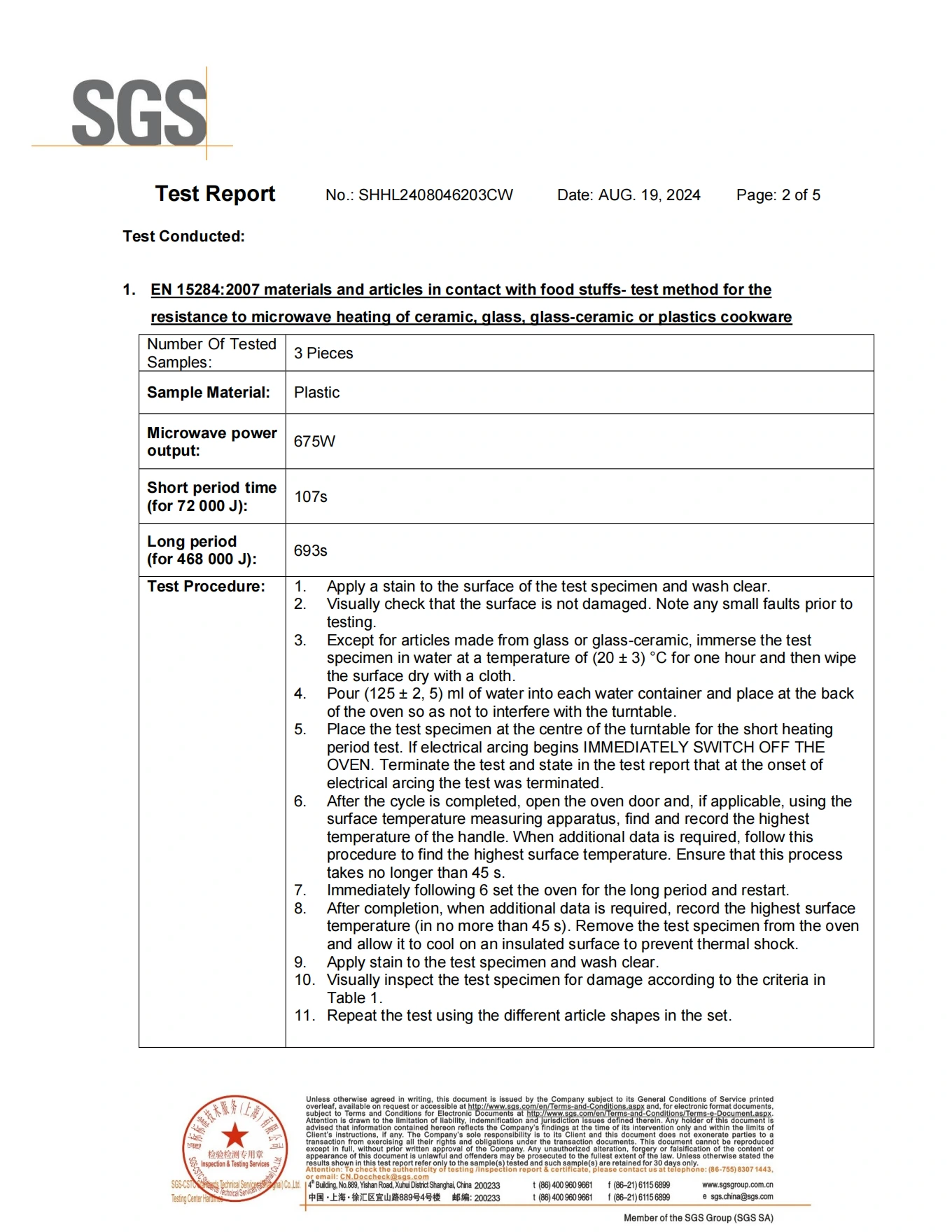

Microwave-Safe & Anti-Fog

Enables clear product visibility during reheating while maintaining hot-food workflows for dine-in, takeaway, and self-service stations, enhancing end-customer satisfaction.

Customizable Flexible

Allows branding, regulatory info, or promotional messages on the lid or base, offering a versatile on-pack communication solution that strengthens brand recognition and supports marketing programs.

Customizable Coffee Cup & Lid

Eco-Friendly Paper Material

Recyclable paper with PE or PLA coating supports sustainability goals, helping operators meet environmental compliance standards while providing a responsible packaging solution.

Leak-Resistant Lid

Secure snap-on lid minimizes spill risks, enhancing operational safety and reducing customer complaints from accidental spills during handling and transport.

Double-Layer Option

Optional double-wall construction improves insulation, ensuring safe and comfortable handling of hot beverages and protecting both staff and customers.

Custom Logo

Print areas enable branding, regulatory information, or promotional messaging, supporting flexible on-pack communication while reinforcing brand visibility across retail and foodservice environments.

Sustainable Production

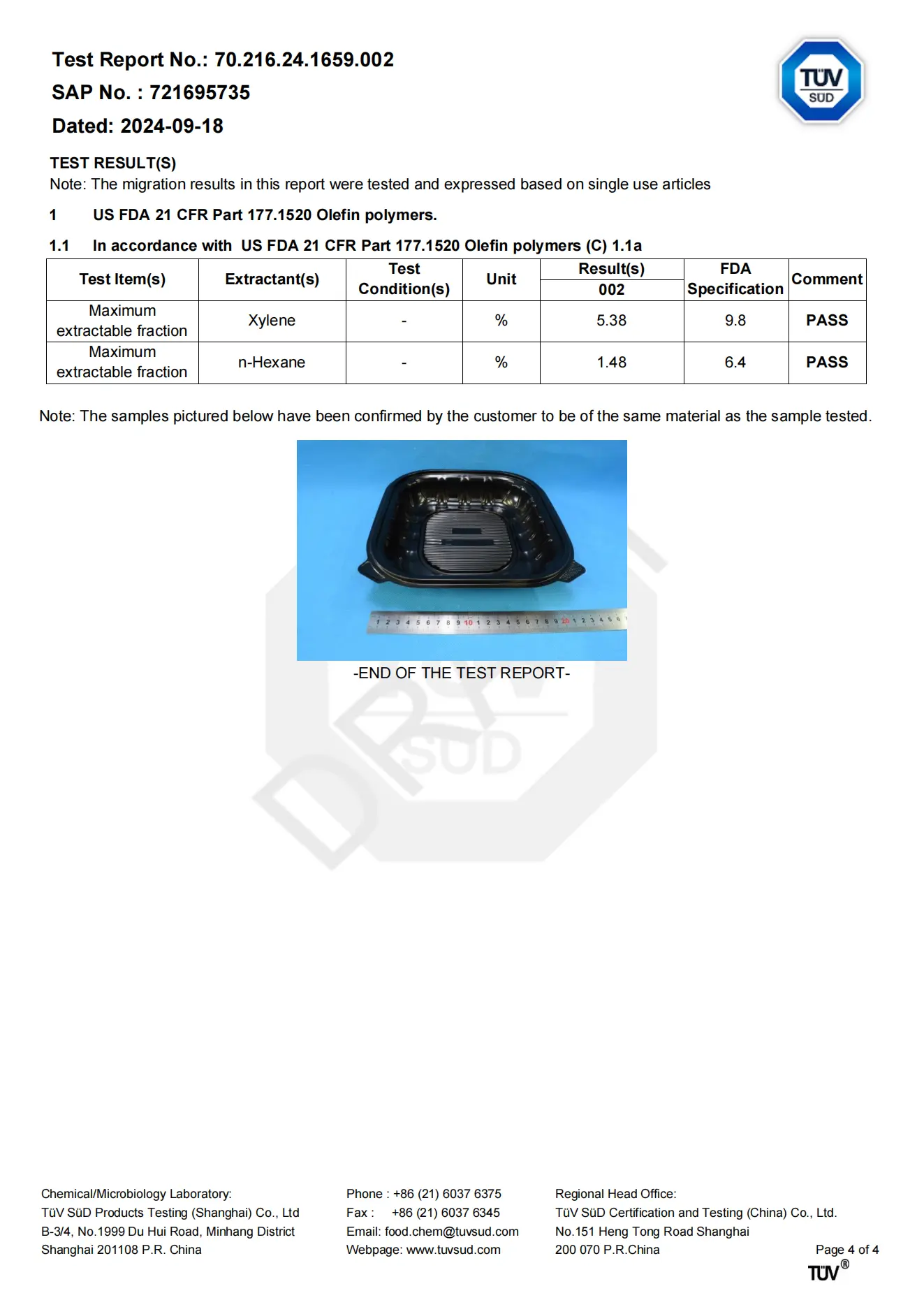

Certified Food-Grade Recycled & Bio-Based Materials

We use 30–50% post-consumer recycled PET sourced from certified recycling facilities. All rPET batches undergo decontamination, IV (Intrinsic Viscosity) restoration, and FDA/EFSA food-contact compliance testing, ensuring full safety for chilled and display packaging. Each batch is documented for traceability, enabling verified environmental benefits without performance loss.

15+ Years of Packaging Expertise

100 million+

Packaging produced annually

Average daily output 300,000

220+

professional team

This includes: 8 excellent mold designers, 10 product development engineers, 30 multilingual foreign trade salespersons, 20 quality control team members, 5 warehouse management personnel, and several skilled packaging technicians in the workshop.

98.8%

Customer satisfaction rate and on-time delivery rate in 2024

Achieved through surveys and internal tracking systems.

40,000㎡

Factory space

5 production workshops: PP/PET/PLA/RPET Sheet workshop + Thermoforming station workshop + Digital printing workshop + Cup making machine workshop

Trusted by Global Food Brands & Distributors

Below are real cases from the clients we serve worldwide.

Dual-Color Hinged Box | U.S. Case

Challenge

Creating a dual-color meal box with precise green and red printing for seasonal promotions posed technical challenges. Many suppliers struggled to maintain color accuracy and alignment across batches, affecting consistency and brand impact.

Solution

JHPKG implemented specialized dual-color molds and patented printing technology, achieving 100% batch consistency in color and alignment. The final boxes enhanced festive appeal, reinforced brand identity, and provided a reliable packaging solution with a daily output exceeding 50,000 units.

- Fast Delivery & Operational Reliability

Produced 500,000 boxes in just 10 days, supporting retailers and foodservice operators with timely seasonal fulfillment. - Accurate Colors

Precise green and red matching ensures consistent visual appeal and strengthens brand perception.

Sealed Tofu Transport Tray | Korea Case

Challenge

Maintaining tofu integrity during handling and transport while presenting premium quality was difficult for conventional trays.

Solution

JHPKG developed custom tray compartments optimized for shock absorption and hygiene, providing a reliable solution that preserves tofu shape and quality throughout storage, transport, and display.

- Enhanced Protection

Structured compartments reduce breakage and deformation, minimizing product loss and customer complaints. - Hygienic Design

Smooth, easy-to-clean surfaces enable professional presentation while meeting food safety standards in restaurants, retail, and catering operations.

Blueberry Packaging Box | Peru Case

Challenge

Clients needed packaging that both protects blueberries and effectively showcases branding to attract buyers. Conventional boxes often failed to combine protection with visual appeal.

Solution

JHPKG applied custom embossed logos on the base and printed lids, providing a reliable fruit protection solution while enhancing brand recognition.

- Brand Visibility

Lid and base designs increase visual appeal, supporting private-label differentiation and marketing initiatives. - Secure Packaging

Robust structure safeguards blueberries during transport and handling, reducing damage and improving customer satisfaction.

Optimized Global Logistics for High-Volume Packaging Supply

Our logistics infrastructure is engineered for large-volume, multi-SKU disposable packaging supply. From production scheduling to container loading and international transport, every stage is optimized to support predictable replenishment cycles, lower freight costs, and stable delivery performance for B2B importers, distributors, and brand clients.

Predictable Lead Times Supported by Integrated Production Capacity

We maintain long-term production scheduling with reserved capacity for recurring B2B orders.

-

Standard packaging SKUs ship within 7–12 days.

-

Complex mixed-SKU orders ship within 12–18 days.

-

Peak-season capacity is stabilized through automated lines and mold-dedicated machines to avoid seasonal delays.

-

Batch traceability from raw material to shipment ensures accurate lead-time forecasting.

Maximized Container Efficiency to Reduce Freight Cost

We engineer carton sizes, nesting depth, and product stacking orientation to increase container utilization.

-

Utilization improved by 20–35% for trays, bowls, cups and lids.

-

Nested structures reduce empty space and lower cost per unit.

-

Laboratory stacking simulations ensure cartons maintain strength at ≥8 layers during sea freight.

-

Optimized packing formats available for 20GP, 40GP, and 40HQ based on your replenishment cycle and distribution model.

Export-Grade Protection for Long-Distance Shipping

All products are protected with reinforced export-grade solutions designed for global transport environments.

-

5-layer corrugated cartons with ≥12–14 kg compression resistance.

-

PE inner bag and optional moisture-proof lining for tropical climates.

-

Edge guards and reinforced seams for heavy SKUs (e.g., PET trays, bagasse bowls).

-

Impact-tested packaging to withstand loading/unloading and cross-docking operations.

-

Carton labels include item codes, batch numbers, and pallet maps for warehouse automation.

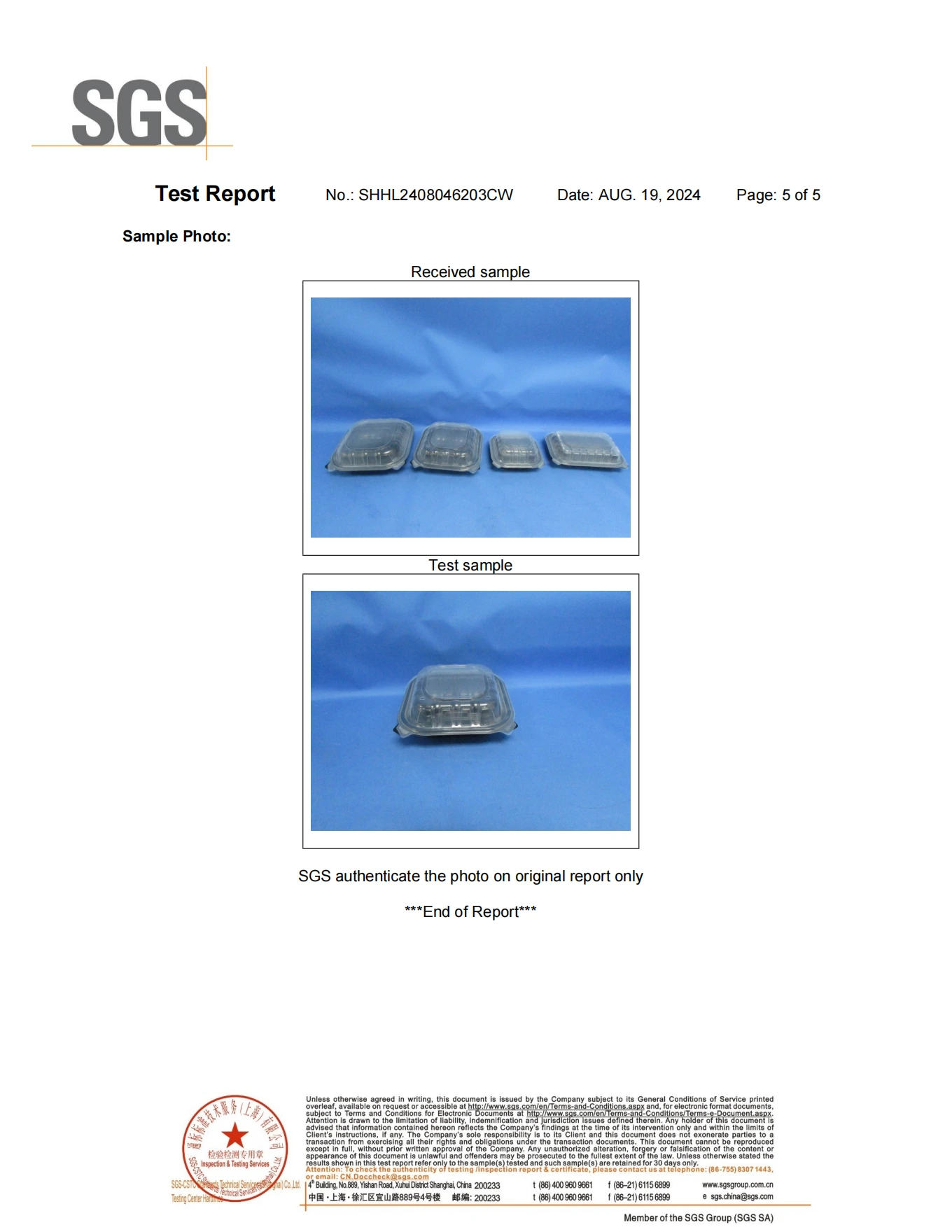

Proven Quality/Verified Compliance

Products are manufactured under strict quality controls and verified compliance standards, ensuring safety, consistency, and confidence for international clients.